We utilize state-of-the-art rolling equipment operated by highly skilled technicians. These technicians experience is critical to ensure the correct amount of pressure and number of passes are used to create the ideal curvature. In addition to our manually operated rolls we have expanded our capabilities with CNC driven rolling equipment. Utilizing the CNC rolling operations we are able to duplicate parts at an exceptional level of accuracy and repeatability.

- Rolling - Sheet and Plate

- Latest technology: 4 - Roll Hydraulic

- Double-pinch Bending Rolls

- 10 gauge through 1" capability

- CNC control on 10 gauge and 1" Rolls

Quick Links to Other Baldwin Metals Capabilities:

Press brake forming is one of our specialties at Baldwin Metals. Our press brake operators are the best in the business and along with CNC equipped press brakes can accurately and consistently form metal spanning from .005 to over 2 inches. In our fleet of press brakes we boast a range of units and have one of the largest press brakes in the southern United States featuring a 600 ton capacity. We typically form parts in our press brakes from stainless steel, carbon steel, chro-moly, aluminum and even titanium. Beyond these standard materials we can supply nearly any type of exotic material for special productions.

Our press brakes see a diverse range of work as they are often times integrally involved in prototyping new products for our clients. The most common press brake work we see spans a wide range of production including cones, brackets, standard angles and angles bumped to any custom radius, pressure vessels, construction equipment, equipment repair, custom parts, counter tops, vent hoods, metal cabinets and industrial prototypes. Ultimately our press brakes see an extraordinarily wide range of products.

Quick Links to Other Baldwin Metals Capabilities:

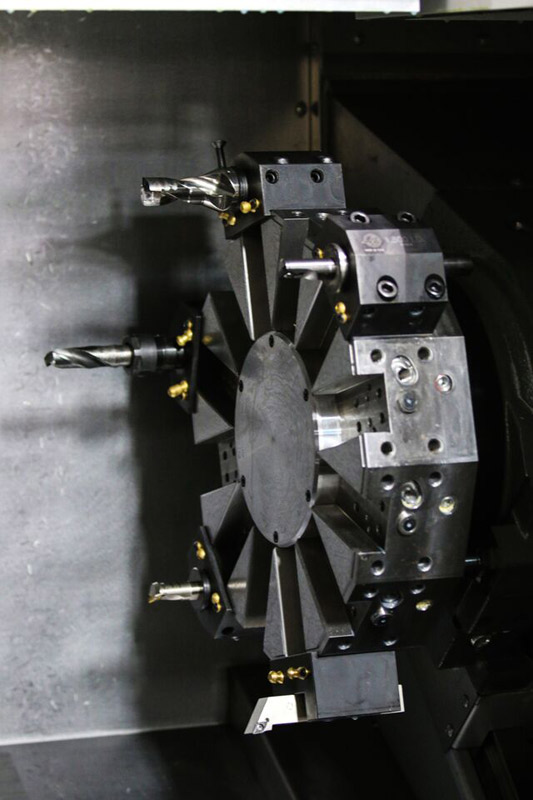

One of the support services within the metal fabrication industry we offer is machining and CNC lathe services. At Baldwin Metals we have made a commitment to continually improve in our machine shop and as a result offer leading lathe services. We utilize multiple, state of the art CNC lathes in addition to manual lathes allowing us to quickly and efficiently produce turned pieces for our clients. We regularly undertake prototype and first-run projects and as a result are adept at re-tooling and quickly getting new jobs up and running. We do threading as well as thread repair, turning, boring, facing, pipe threads (straight and tapered), and groove custom shafts, spacers and bushings. Our lathe's are capable of handling shafts up to 28 inches in diameter and 20 feet in length. We turn numerous materials including stainless steel, carbon steel, aluminum, titanium and can supply other exotic materials.

To learn more about our lathe and turning services please call 214-747-6722 to speak with one of our production specialists or email This email address is being protected from spambots. You need JavaScript enabled to view it.

Metal rolling equipment acurately rolls pipe as well as angle, t-beams, channel, flat bar, square tube, rectangular tube, standard metal pipe, wide flange beam, rail and pipe

Metal rolling equipment acurately rolls pipe as well as angle, t-beams, channel, flat bar, square tube, rectangular tube, standard metal pipe, wide flange beam, rail and pipe  Our largest lathe offers turning services to long and large metal pieces

Our largest lathe offers turning services to long and large metal pieces Our manual lathes offer fast services for turned pieces as well as threading, thread repair, boring, facing, pipe threads (straight and tapered), and grooving custom shafts, spacers and bushings

Our manual lathes offer fast services for turned pieces as well as threading, thread repair, boring, facing, pipe threads (straight and tapered), and grooving custom shafts, spacers and bushings

Quick Links to Other Baldwin Metals Capabilities:

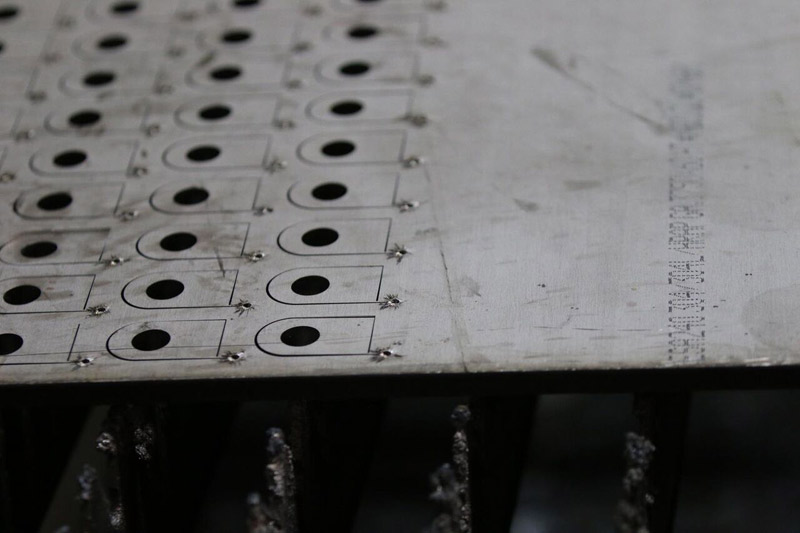

Baldwin Metals is a leading provider of laser cutting services in the Dallas and Fort Worth area. The majority of our sheet metal fabrication projects start with our laser cutting equipment, which can accurately cut sheet metals to exacting dimensions. Among the materials our laser-cutting machine can cut includes stainless steel, carbon steel, mild steel, aluminum and titanium. Beyond these materials we can supply many other exotic materials. Our laser cutting equipment can handle sheet metal as thin as 30 gauge and as thick as ¾ inch. With an automated loading table our laser cutting equipment runs very efficiently and can handle larger production runs.

To learn more about our laser cutting services please call 214-747-6722 to speak with one of our production specialists or email This email address is being protected from spambots. You need JavaScript enabled to view it.

Quick Links to Other Baldwin Metals Capabilities:

Baldwin Metals offers an extensive range of milling services. Whether you need drilling, threading, tapping, slotting, keyways, contouring, boring or other vertical milling services Baldwin Metals can help. Our state-of-the-art mills allows us to produce custom pieces ranging from special fasteners to complex machined components for a variety of functions. Within our machining department we utilize both manual and CNC mills. We build sub-assemblies, brackets, base plates, prototypes and other custom metal parts with our mills. While we undertake a wide range of jobs we often mill carbon steel, stainless steel, aluminum, brass, teflon, and other plastics and metals.

To learn more about our milling services please call at 214-747-6722 to speak with one of our production specialists or email This email address is being protected from spambots. You need JavaScript enabled to view it.